PIN GRADING POLICY

We do not classify our pins in terms of grade as we believe that all pins should meet a minimum level of acceptable quality to be sold and the practice could be used to artificially inflate the cost to a buyer that is considered as an unethical anti-consumer practice. Pins are handmade and it is unethical to judge them according to an arbitrary perfection scale determined solely by the maker. Due to the standard production process of our pins by hand by our manufacturer please note that there may be small imperfections in your pin. Upon purchasing your pin you agree that you have accepted this Grading policy.

We strive for the best quality possible, all pins are handmade, as such, you may notice minor cosmetic imperfections such as minor scratches, enamel under-fill, or dust particles. See below for a full list of potential imperfections. Pins are inspected in natural light, at eye level, from a distance of 10-12". Any major imperfections from inspection that seriously affect the look of the pin will be removed from circulation.

POSSIBLE MINOR COSMETIC IMPERFECTIONS

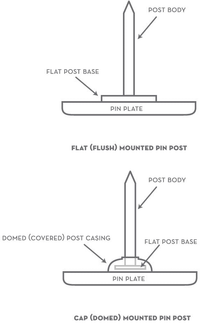

• Slight enamel under-fill • Slightly off-set screen printing (screen printing is hand-pulled paint and exact location can fluctuate by up to 1mm in any direction) • Micro air bubbles • Light particles of dust in enamel • Missing enamel in very small areas that are difficult to fill • Wobbly or broken post: Please note that we always use 1-2 posts more than necessary due to rare instances where a pin might break in transit. Compared to standard double-post, all our pins are typically triple-posted or quadruple-posted. Wobbly posts are part of the feature in pin manufacturing to prevent the post from snapping off completely. • Small dents/nicks/scratches, which can sometimes occur during the grinding and polishing process (please note, sometimes large flat surfaces of enamel or raised metal will show micro-scratches at an angle due to the polishing process. These are only noticeable with use of angled light) • Imperfections on the sides or the back of pins will not be taken into consideration in the inspection process.